- 可靠的质量: 近10年的设计制造经验。严把质量关。

- 优异的性能: 知名企业以及跨国公司制定OEM厂家.

- 先进的工艺: 使用寿命是同行业3-4倍.

- 电话:86 10 80843966

- 传真:86 10 80843978

- 电子邮件:huagreat2007@126.com

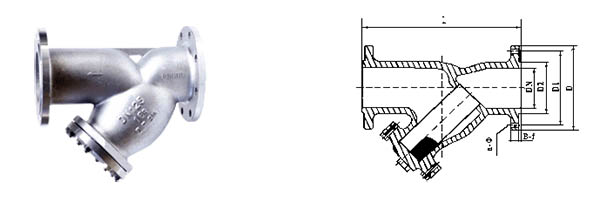

Product Overview

Y-strainer is an indispensable equipment in the medium transmissing pipline network. it could used in the filtration of liquid, gas and media contains large particles.by removing large solid impurities, make sure mechine and equipment (including compressors and pumps), instrument work properly. when fluid flows ino spcified fliter gauze, the impurities would be blocked, the clear fluid will flow out from the other side, when it need clean, just assembly the fliter gauze, and clean it up and put it back. it's very convenient.

Applicable fields

- Weak corrosive materials in the processing of petrochemical, such as: water, ammonia, oils, hydrocarbon, etc.

- Low temperature material in the processing of refrigeration: such as: liquid methane, ammonia, and other refrigeration fluids.

- Sanitary required materials in the foods and medicine producing, such as: beer, dairy products, and medicine appliances, etc.

Gerneral Principle

- Import/Export Diameter:In principle, Strainer diameter should not less than import diameter of pump, it's normal same as this diameter.

- Nominal Pressure:The Pressure Lever is comfired according to the Maximum pressure of filtration pipenetwork.

- Mesh number: Based on size of impurities, please check the mesh specification table.

- Materials: Normally the Materials of Strainer is same as pipeline, but for different working condition should select Cast iron, Carbon Steel or low alloy steel or stainless steel filter.

- 5、Pressure:For water, normally pressure loss would be 52~1.2kpa 。

Optional Materials for Parts

| Name | Optional Materails |

|---|---|

| Shell Bonnet | Cast iron, Cast steel, Stainless Steel |

| Filter Net | Carbon Steel, Stainless Steel |

| Spacer | PTFE |

| Thread & Nut | Carbon Steel, Stainless Steel |

Adoption Standard

Overall Dimensions

| Specs | Nominal Pressure | L | D | D1 | D2 | B-f | n-Ф | |

|---|---|---|---|---|---|---|---|---|

| mm | in | |||||||

| DN32 | 1 1/4” | PN16 | 180 | 135 | 100 | 78 | 16-2 | 4-18 |

| PN25 | ||||||||

| DN40 | 1 1/2” | PN16 | 200 | 145 | 110 | 85 | 16-3 | 4-18 |

| PN25 | 18-3 | |||||||

| DN50 | 1” | PN16 | 220 | 160 | 125 | 100 | 16-3 | 4-18 |

| PN25 | 20-3 | |||||||

| DN65 | 2 1/2” | PN16 | 250 | 180 | 145 | 120 | 18-3 | 4-18 |

| PN25 | 22-3 | |||||||

| DN80 | 3” | PN16 | 280 | 195 | 160 | 135 | 20-3 | 8-18 |

| PN25 | 22-3 | |||||||

| DN100 | 4” | PN16 | 320 | 215 | 180 | 155 | 20-3 | 8-18 |

| PN25 | 230 | 190 | 160 | 24-3 | 8-23 | |||

| DN125 | 5” | PN16 | 360 | 245 | 210 | 185 | 22-3 | 8-18 |

| PN25 | 270 | 220 | 188 | 28-3 | 8-25 | |||

| DN150 | 6” | PN16 | 430 | 280 | 240 | 210 | 24-3 | 8-23 |

| PN25 | 300 | 250 | 218 | 30-3 | 8-25 | |||

| DN200 | 8” | PN16 | 485 | 335 | 295 | 265 | 26-3 | 12-23 |

| PN25 | 360 | 310 | 278 | 34-3 | 12-25 | |||

| DN250 | 10” | PN16 | 595 | 405 | 355 | 320 | 30-3 | 12-25 |

| PN25 | 425 | 370 | 332 | 36-3 | 12-30 | |||

| DN300 | 12” | PN16 | 605 | 460 | 410 | 375 | 30-3 | 12-25 |

| PN25 | 485 | 430 | 390 | 40-4 | 16-30 | |||

| DN350 | 14” | PN16 | 715 | 520 | 470 | 435 | 34-4 | 16-25 |

| PN25 | 550 | 490 | 448 | 44-4 | 16-34 | |||

| DN400 | 16” | PN16 | 785 | 580 | 525 | 485 | 36-4 | 16-30 |

| PN25 | 610 | 550 | 505 | 48-4 | 16-34 | |||

| DN450 | 18” | PN16 | 855 | 640 | 585 | 545 | 40-4 | 20-30 |

| PN25 | 660 | 600 | 555 | 50-4 | 20-34 | |||

| DN500 | 20” | PN16 | 900 | 705 | 650 | 608 | 44-4 | 20-34 |

| PN25 | 730 | 660 | 610 | 52-4 | 20-41 | |||

Installation and Maintenance:

- 1. Y type filter could be installed in vertical or horizontal, the direction of flow should be in accordance with the the arrow indication.

- 2. The filter cartridge should be cleaned up in case pressure loss increased due to the effection of impurities inside of the filter after using for a certain time.

Actual Photo